Input Module: First it needs to be dismounted. Remove all screws from the back

plate and also three knobs. Remove knobs carefully using something plastic

to lever them of, they are friction fitted only. Behind the knobs are

retaining nuts, use a fine pointed needle nose pliers to remove. The PCB

may not yet come free, it seems that in some cases the thick gasket is

glued and you may need a very sharp blade to cut free.

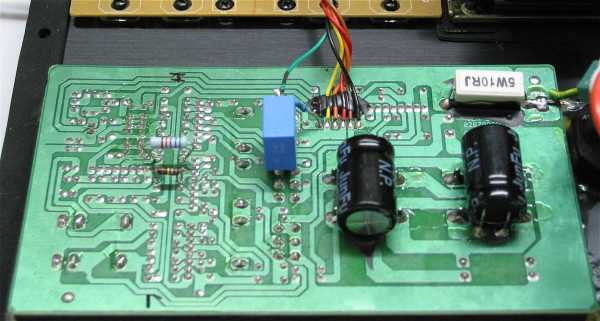

Desolder and remove R26 and R27 from PCB. The PCB is now remounted,

the new R26 and R27 will be fitted on the rear of the PCB. See photo blow.

The new R26 (56K) and R27 (180K) can clearly be seen on the left side of

PCB.

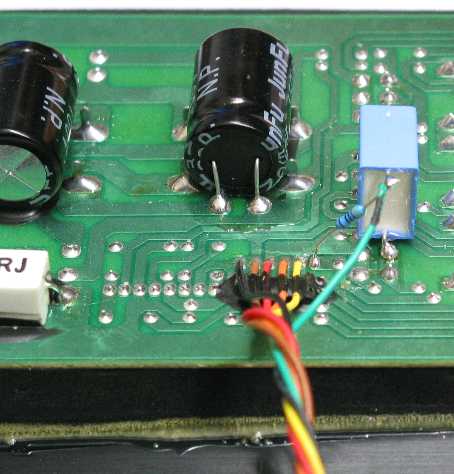

On the Output of Input

Module: Now unsolder the Green Wire that is part of the wiring harness to

Power Amp Module, it is right on the end next to the Yellow wire. Solder 470R to the point where

you removed wire, now wire Green Wire to other side of 470R. Also from

this junction, add 0.33uF to a ground point. Study the photo below

carefully. Please note carefully where the 0.33uF Cap is grounded

on the PC Board.

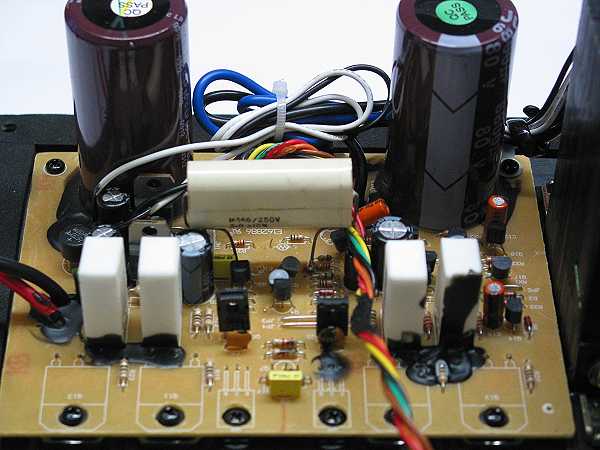

Power Amp Module: Finally, and this is a little tricky, we need to replace the yucky

4.7uF electrolytic used input coupling cap. Cut away old C1 with sharp

pliers, chances are you will destroy it in the process of removing. Next

stage is tricky, wee now need to fit 3.3uF film cap. But this cannot be done unless you would

like to remove the whole module, not recommended. Instead it can be fitted

to other components with ends exposed enough to be soldered to. These are

R1 and R2. Please look carefully at the photo and illustration shown

below. You will need a very fine pointed solder tip, pre-solder the

correct ends of R1 and R2. Also pre-solder the ends of 3.3uF cap, as this

will assist in a tricky job. Do not overheat. Finally use a little bit of silicone glue to

mechanically stabilise cap (not shown).

This requires good soldering

skills

The work is now concluded, please check and

double-check everything, And when you have done that, then triple-check.

Beware that you have no warranty to go back on.

If you have any doubts whether you have the skills, do

not proceed. It may be worthwhile to find a qualified technician,

show him this page and let him proceed. Please understand YOU are

responsible for the end result and YOU have been warned!

See Box Construction Page for detailed Drawings, Cutting Sheet and other

Box Diagrams

See User Setup Page for Operating Instructions.